what is major and minor load in rockwell hardness test|rockwell hardness tester : Brand After the preload, an additional load, call the major load, is added to reach the total required test load. This force is held for a predetermined amount of time (dwell time) to allow for elastic recovery. Soccer24.com is your ultimate destination for live soccer scores, results and betting odds from over 1000+ leagues worldwide. Whether you are interested in EPL, LaLiga, Serie A, UCL or any other soccer competition, you can find the latest updates, standings and odds on Soccer24.com. Follow your favorite teams, players and matches, and get notified of the .

{plog:ftitle_list}

Resultado da About this movie. arrow_forward. The saga of good versus evil continues as the VKs Mal, Evie, Carlos and Jay return to the Isle of the Lost to recruit a new batch of villainous .

determination of knit fabric strength by bursting strength tester

rockwell hardness testing scale

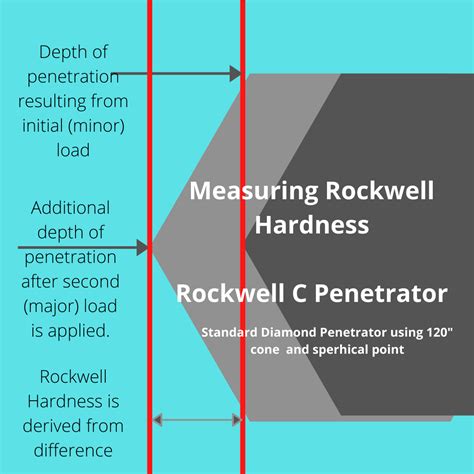

Principle of Test. The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied light (minor) load (SET point).Superficial Rockwell Testing. In this test method, the minor (preload) is always 3 kgf. The major load may be any of the following loads: 15kgf, 30 kgf, or 45 kgf. ASTM E18 contains a listing of all regular Rockwell scales and typical .After the preload, an additional load, call the major load, is added to reach the total required test load. This force is held for a predetermined amount of time (dwell time) to allow for elastic recovery.

rockwell hardness testing guide pdf

There are two types of Rockwell tests: • Regular Rockwell: the minor load is 10 kilograms of force (kgf) and the major load is 60, 100 or 150 .

First a Minor Load (one of a lesser force) is applied to a steel ball or sphero—conical diamond penetrator. Then, while the Minor Load is still being applied, a Major Load (one of greater force) is applied at a precisely .In a Rockwell hardness test, initially a minor load of 10 N is applied and the zero datum position is established. The major load (60, 100, or 150 N) is then applied for a specific period (a few .

Next, a secondary load, called the major load, is added to attain the overall test load. This force is sustained for a pre-specified length of time to allow for elastic recovery. The major load is then released, and the preliminary .The Rockwell Hardness Test uses a depth-differential method to test for hardness. A predetermined minor load is applied to the test sample, and the depth measurement is taken. .

Unlike the Brinell test, the Rockwell hardness tester uses a smaller indenter and starts by applying a minor load to cut through the surface. This process makes it less destructive and more accurate.The hardness determination obtained represents the additional depth to which the Major Load has indented the test specimen beyond the initial indentation of the application of the Minor Load. The displayed indication is proportionally .The Rockwell hardness test method, as properly defined in ASTM E-18 standards, is the most commonly used hardness test method among all the other methods. + 86 755 61301520; . D = The difference in heights between .Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 kgf. Superficial Rockwell Testing. In this test method, the minor (preload) is .

• Regular Rockwell: the minor load is 10 kilograms of force (kgf) and the major load is 60, 100 or 150 kgf. • Superficial Rockwell: the minor load is 3 kgf and major load is 15, 30 or 45 kgf. In both tests, the indenter may be either a diamond cone or steel ball, depending on the characteristics of the material being tested. Rockwell ScalesIn the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.Definition of the Rockwell hardness test method The Rockwell hardness test methods are described by a number of scales, characterized by a standard, an indenter type, and a load. Examples of Rockwell hardness test methods: HRE 1/8” diameter tungsten carbide ball indenter, 100 kgf major load Superficial Rockwell Hardness Testing Deep Dive into Rockwell Hardness Testing. The Rockwell method is the gold standard for measuring a material’s resistance to indentation. The process involves an initial minor load, .

The Rockwell hardness test is based on the measurement of the depth to which an indenter is forced by a heavy (major) load beyond the depth resulting from a previously applied preliminary (minor) load. The test follows the sequence, see Figure 23.4 to your right: Application of minor load. A ‘zero’ position is recorded. Gradual application .3.1. Rockwell Hardness Test. . Upon removal of the major load, the depth reading is taken while the minor load is still on. The hardness number may then be read directly from the scale. . The difference in the depth of the indentation between the minor and major loads provides the Rockwell hardness number. There are several Rockwell scales .Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). Rockwell Hardness Tester: It has an automatic load application system and accurate depth measurement for increased speed of testing and repeatability. One vital feature it has is its ability to test a range of metals as well as alloys with less sample preparation making it useful in industry.

This article discusses rockwell hardness testing, its applications and uses. . an initial test force, frequently called preload or minor load, is put to a sample. . a secondary load, called the major load, is added to attain the overall test load. This force is sustained for a pre-specified length of time to allow for elastic recovery. The .

The Rockwell Hardness Test is actually one of several tests aimed to gauge a material’s compatibility as a component to an object based on their strength and durability. . the minor load is maintained all throughout the test. Some variations of the test would require that the major load remain on the material until it the indent it has made . When Rockwell hardness testing, a minor load of 10kg is applied to the indenter used on the material being tested. The purpose of the minor load is to penetrate the material’s surface and establish a set position. After the minor load is applied, the major load is applied. Again, this major load is dependent on the type of indenter used.

This set of Testing of Materials Multiple Choice Questions & Answers (MCQs) focuses on “Rockwell Hardness Test”. 1. Which hardness test is most widely used in the US? a) Brinell b) Vickers c) Shore d) Rockwell View AnswerThe Rockwell Hardness Test is one of several tests used to determine whether a material is solid and durable enough to be employed as a component of an object. The Knoop, Brinell, and Vickers procedures are additional . The Rockwell hardness test involves applying a sequence of loads to the material and measuring the depth of the resulting indentation, which indicates the material’s hardness. . Apply major load. Once the minor load is stable, apply the major load. The major load can range from 60 to 150 kgf, depending on the specific Rockwell scale being .The Rockwell hardness test is applied globally for the application of an experimental indentation hardness test. The Rockwell test is a quick process, very cost-effective, and non-destructive test (causing only minor indentation on the specimen material). The Rockwell hardness test is a simple process that is why it can be performed by anyone .

The Rockwell scale applies a minor load followed by a major load. The hardness value is then noted directly from a dial. . Other than the Rockwell method of hardness testing, there are varied methods such as Brinell, Vickers, and Leeb tests. Though it is not possible to provide a precise conversion in most of the cases, it is easier to . The Rockwell hardness test is a method used to measure the hardness of metallic materials, essential in industry, engineering and design to ensure the . the indenter is inserted into the test material under a preliminary minor load and this depth is recorded. With the minor load still applied, an additional load, known as a major load, is .

rockwell hardness testing definition

The Rockwell hardness test procedure involves applying an initial minor load to a sample, followed by a major load, then removing the major load while maintaining the minor one. The depth of indentation caused by the loads determines the hardness value.

rockwell hardness tester

Rockwell Hardness Test: This method assesses the depth of indentation caused by a specific load on the material’s surface. It’s highly versatile and straightforward, making it widely used across industries. . While both tests involve applying a load to induce plastic deformation, they differ in the direction of force (compressive versus . With the minor load still applied an additional load is introduced known as the major load which increases the depth of penetration on the sample. The Rockwell hardness number is calculated from the depth of permanent deformation of the indenter into the sample, i.e. the difference in indenter position before and after application of the major . Study with Quizlet and memorize flashcards containing terms like Which of the following statements is true about microhardness testing?, Which portable hardness testing method measures the rebound of a ball hammer that is bounced off of the material with a spring mechanism?, Which hardness testing method determines a hardness value after delivering .

The Rockwell hardness test is based on the measurement of the depth to which an indenter is forced by a heavy (major) load beyond the depth resulting from a previously applied preliminary (minor) load. . Rockwell: the minor load is 10 kgf, the major load is 60, 100, or 150 kgf. Superficial Rockwell: the minor load is 3 kgf and major loads are .

digital board mullen burst strength tester

4.1 A Rockwell hardness number is a number derived from the net increase in depth impression as the load on an indenter is increased from a fixed minor load to a major load and then returned to a minor load (Procedure A). A Rockwell alpha (α) hardness number represents the maximum possible remaining travel of a short-stroke machine from the net .The Rockwell hardness test method, as defined in ASTM E-18, is the most commonly used hardness test method. . Minor Load: Major Load: Typical use: HRA: Spherical diamond: 98.07 N (10 kgf) 588.4 N (60 kgf) Cemented carbides, thin steel, and shallow case hardened steel: HRB: Ball, 1.588 mm (1/16 inch)

digital bursting strength tester manufacturers

Previsão para 15 dias Salto de Pirapora - SP. Sol e aumento de nuvens de manhã. Pancadas de chuva à tarde e à noite. Alta probabilid. Sol com muitas nuvens durante o dia. Períodos de nublado, com chuva a qualquer hora. Sol, com pancadas de chuva de manhã e muitas nuvens à tarde. À noite, tempo firme. Sol com algumas nuvens.

what is major and minor load in rockwell hardness test|rockwell hardness tester